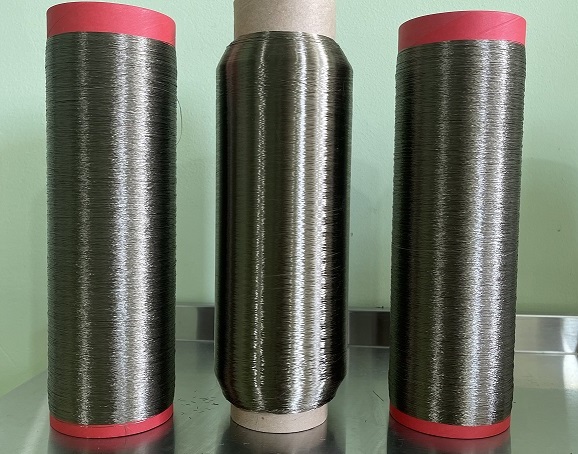

CBF roving is a complex thread of straight-directed CBF monofilaments, wrapped on a special spool and externally unwound, with a given Tex range of 22 – 150 Tex (bigger Tex might be produced on customer’s request).

CBF roving from UBT is obtained as a result of the usage of its own recipe for mineral enrichment of basalt-andesitic lava, as well as its own technological and production know-how.

Depending on the customer’s needs, CBF can be produced in the form of thin (7-9 μm of monofilament diameter) and super thin (5-7 μm of monofilament diameter).

CBF from UBT is the thinnest, allowing for the production of strong and ultra-lightweight basalt products with increased physical and mechanical characteristics of the end-use composite product. At the same time, such products will maintain outstanding chemical properties and durability.

Typical CBF applications include weaving, braiding, high-speed knitting, filament winding, UD-impregnation and pultrusion, chopping and also when CBF is necessary to be used in applications requiring high mechanical properties, well wet-out and high infusion with organic matrices, in thermoset matrices like epoxy resin or polyester, vinyl ester as well as in many thermoplastic systems.