CBF Properties

Continuous Basalt Fiber – (hereinafter – “CBF”) is a unique inorganic product based on mineral material, which has natural properties of high mechanical strength as well as tear wear, impact, corrosion, high thermal and chemical resistance, lightweight and environmental friendliness.

The main properties of CBF are:

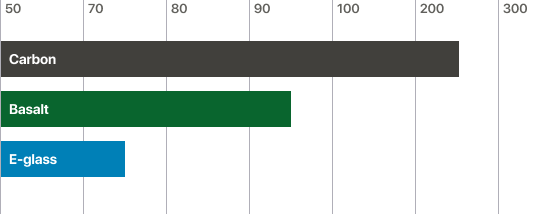

- Extremely high chemical resistance in acidic and alkaline environments.

- Good adhesion to various materials.

- Does not accumulate static electricity. Very high resistance to electromagnetic emanation.

- 100% dielectric.

- Transparency to radar radiation.

- It does not suffer from corrosion, is rust-free, and is stable in any liquid or gaseous medium.

- Lightweight and high mechanical strength, which allows you effectively to reinforce the product.

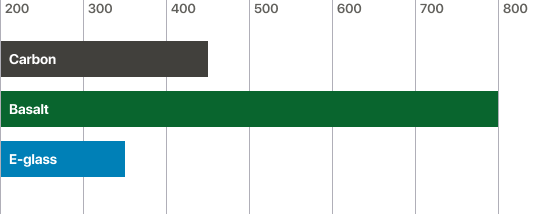

- High thermal stability. Extended range of application temperatures (from -260 °C to +800 °C, withstands up to +1000 °C in the short term).

- High resistance to radiation and UV.

- Incombustibility.

- Excellent sound and vibration insulation properties.

- Effective fire and thermal protection.

- Anti-catastrophic – high ability to preserve the integrity of the CBF product in case of severe damage.

- Ecological, natural material, safe for human health and for the environment.

- 100% recyclable.

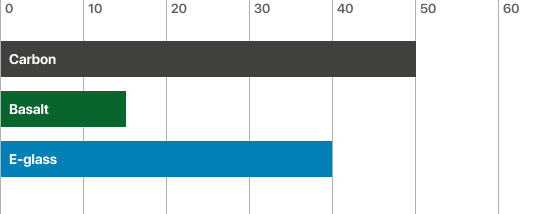

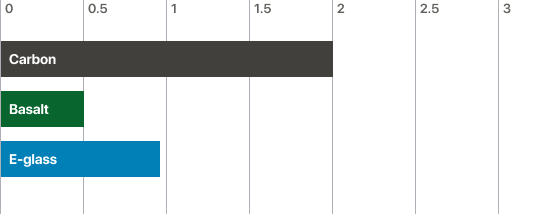

Tensile strength, MPa

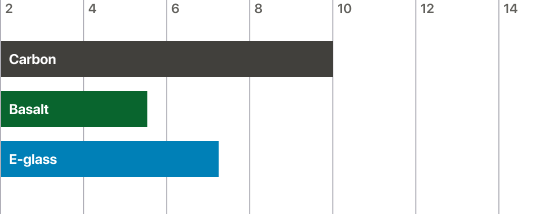

Maximum service temperature, °С

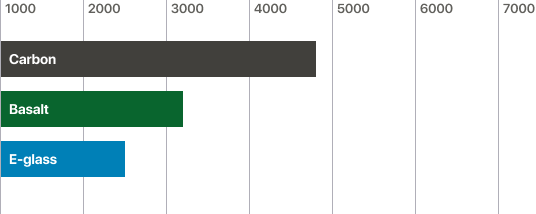

Tensile modulus, GPa

CBF’s physical and mechanical characteristics approach the ones more expensive carbon fiber and are superior to fiberglass. CBF has a high tensile strength of (3000-4800 MPa, which is 20-25% higher than E-fiberglass and 25-50% higher than steel) and a tensile modulus of (85-105 GPa, which is 10-15% higher than E-fiberglass).

In addition, CBF has unique properties that, in combination with other properties, are not found in other fibers. CBF has a high ability to bond with plastic, adhesives, glass, carbon, and other fibers. Therefore, CBF is a convenient material for use in various technologies such as weaving, braiding, knitting, forming, filament winding, UD-impregnation, pultrusion, 3D printing, chopping, spraying, and other “cold technologies”.

In many cases, CBF is an undisputed alternative to its use in composite products, and also has opportunities for its use in combination with other fibers. The unique combination of properties makes CBF completely compliant with the technical requirements of hi-end applications.

% of weight loss after 3 hours’ boiling in water

% of weight loss after 3 hours’ boiling in alkali

% of weight loss after 3 hours’ boiling in acid