Transportation

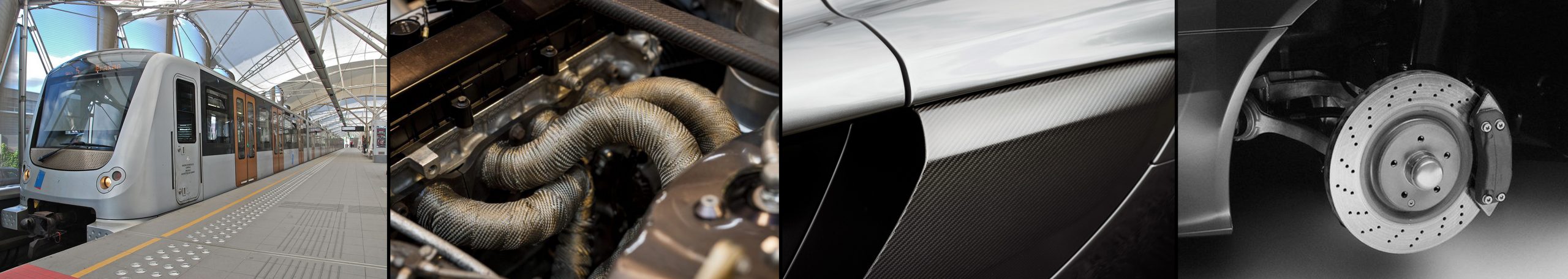

The modern transport industry is developing dynamically by replacing traditional materials with composite ones. The advantages of CBF products, such as heat and sound absorption, strength, durability, environmental friendliness, resistance to aggressive liquids, and anti-corrosion exceed the properties of E- or S-fiberglass and are evident in an application for any type of vehicle.

The use of carbon fiber in the transport industry is often overengineered, due to the lack of alternatives, and its physical and mechanical properties are not in full demand, given its cost.

In many cases, the replacement of carbon fiber or its combined use with CBF will significantly reduce the cost of auto parts and components, without any harm to the physical and mechanical properties or design of such parts, in some cases even improving them.

In the scenario of carbon fiber usage in the form of aesthetic decoration, the r

CBF fabrics and tapes have a wide range of applications and are well suited for the production of structural or body components of any kind of vehicle, as well as for heat, sound, vibration, and electrical insulation, battery trays and cases for EVs, the manufacture of any containers or tanks.

Chopped CBF is perfectly suite